By selecting our innovative product, THE EDGE Super-Cor Flange Connection, for a vent raise project, the Escobal Mine team saved valuable time and money over ringset and lagging or concrete alternatives. In addition to cost, our speed of engineering, manufacturing, delivery and installation were key factors in their decision.

Safe, strong, versatile; structures can now be built from either side

Because THE EDGE Super-Cor Flange Connection can be built from either side, the product is ideal for underground applications like mine shaft liners, ventilation raises and ground support structures.

Improving on an already-accelerated schedule

Noticing THE EDGE Super-Cor Flange Connection on ailmining.com, the contractor contacted us in November of 2012. After reviewing the design particulars and presenting a budget offer, an order was placed on December 21, with the condition that all materials needed to be shipped to Guatemala in March of 2013, at the latest.

AIL Mining’s continuous contact with the contractor, the owner and the geotechnical team helped everything stay on track and all components were shipped two weeks ahead of schedule. The last shipment arrived by April 19 and construction started immediately afterward with a 2.2 m Alimak Raise pilot hole:

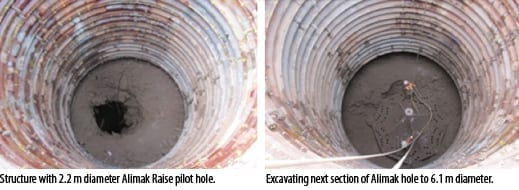

- Alimak Raise from bottom of shaft elevation: The vent shaft construction began with an Alimak Raise — a 2.2 m diameter pilot hole excavated upward from the bottom of the shaft elevation.

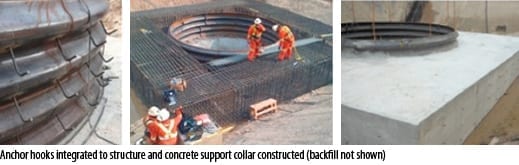

- Six rings of structure placed on top of Alimak opening: Six rings of Four-Flange Structural Liner structure were constructed off to the side and placed on top of this pilot hole.

- Concrete collar and backfill added: An integrated concrete collar was cast on the exterior of the structure and backfilled to the six-ring height.

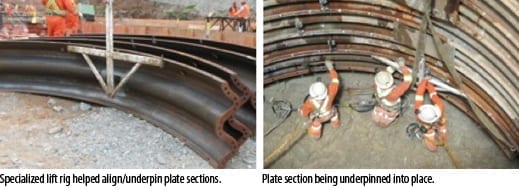

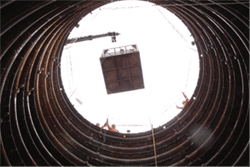

- Downward excavation began inside the liner: Excavation began on the inside of the liner increasing the Alimak hole’s diameter from 2.2 m to 6.1 m. As the excavation progressed downward, liner plates were added by “under-pinning” the rings, one at a time.

- Two rings, base form and grout installed: Once two rings were assembled, a base form was installed and grout was pumped into the exterior void between those liner rings and the excavated soil/rock shaft wall.

- Repeat above sequence for rest of structure: Once the grout had set, the excavation progress continued until the bottom of the shaft liner elevation was reached.

An AIL Mining representative was on-site during construction and field reports indicated the client was very pleased with the The Edge Super-Cor Flange Connection solution and the level of service provided.