A prominent Canadian mine in Northern Saskatchewan was the latest crusher wall to use AIL’s MSE Wire Wall System with our new simplified Track-Strip Soil Reinforcement System to retain the soil mass behind the walls.

Innovative Track-Strip Soil Reinforcement System saves time and money

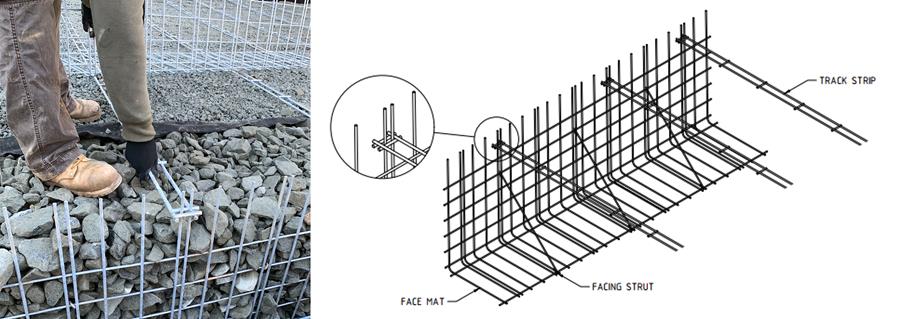

Track-Strips make the walls easier to design, store on the job site and construct — resulting in greater project savings. This innovative system consists of standard 8′ L-shaped basket facing pieces, struts and the Track-Strips — all much easier to stack, ship and handle compared to our traditional wide mesh system.

The Track-Strips have a pair of double transverse wires at the ends, allowing them to be quickly placed over the face panel’s wire uprights for an easy connection before the next face panel slides over top.

Crusher wall project challenged by major forest fires and detours

We kept the project on schedule by ensuring there was a steady stream of communication with both the owner and the contractor, Nahanni Construction Ltd, throughout the process. This included multiple site meetings with the contractor on the layout and the location of the wall. Our logistics team worked closely with our specialized freight carriers and the contractor to ensure our product arrived in a timely manner.

Shipping components to the remote site and our own site visits were challenged by the extreme wildfire conditions in Saskatchewan and Manitoba. Our Technical Service reps drove through guided detours and incurred flat tires while travelling to the site.

In the end, everything came together as planned and the client noted that our wall was high quality and easy to put together.