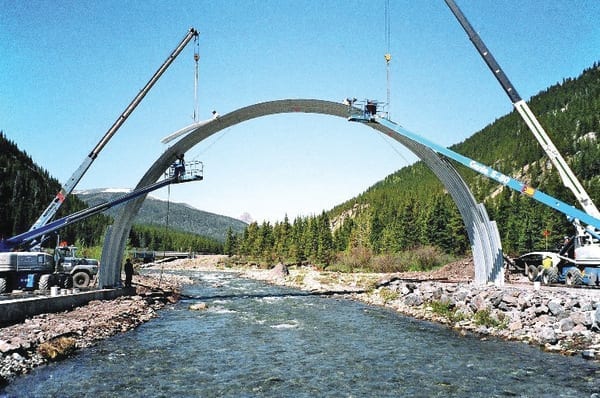

When Cardinal River Coal needed to transport raw coal from their new Cheviot Creek pit through the Canadian wilderness to their processing plant over 20 km away, they faced big challenges. One of the biggest was engineering a structure on the haul road that would be large enough to span Whitehorse Creek, and strong enough to withstand the weight of the world’s largest mining equipment, including a 2.4 million pound shovel. After reviewing several alternatives, Cardinal River chose AIL due to their engineering expertise and innovative products. The finished product turned out to be the largest corrugated arch in the world.

From site prep to assembly

From the time of order, engineering of the arch structure was completed within one month. An additional month was needed for revisions and changes, due to site constrictions. Site preparation began in early May lasting until mid June, and assembly of the Super-Cor Arch was completed within three weeks. Backfilling and wall assembly was then completed within six weeks.

AIL on-site specialists go over and above

AIL provided on-site technical assistance throughout the construction. That assistance ranged from training crews on optimum assembly methods and providing input on solutions to construction issues such as backfill quality and compaction methods, and providing expertise on its wire wall system for installation efficiency. “AIL provided on-site technical specialists that were phenomenal,” says Wes Erickson of Formula Contractors Ltd. “They went to great lengths to help us provide quality workmanship, increase our production, and achieve our very tight schedule.” Over and above, AIL provided research engineers to conduct three days of testing to determine the strain induced on the structure by the heaviest vehicles.